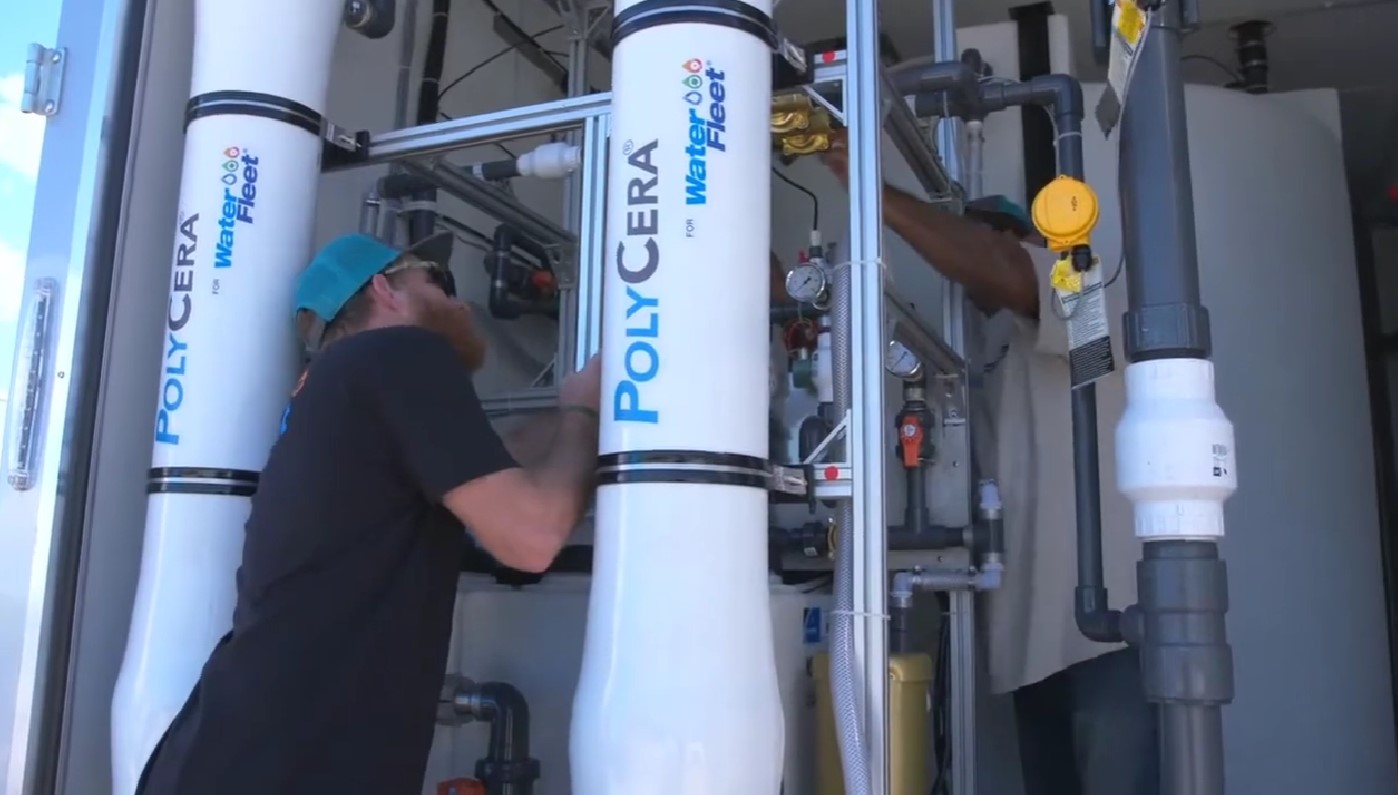

POLYCERA MEMBRANE

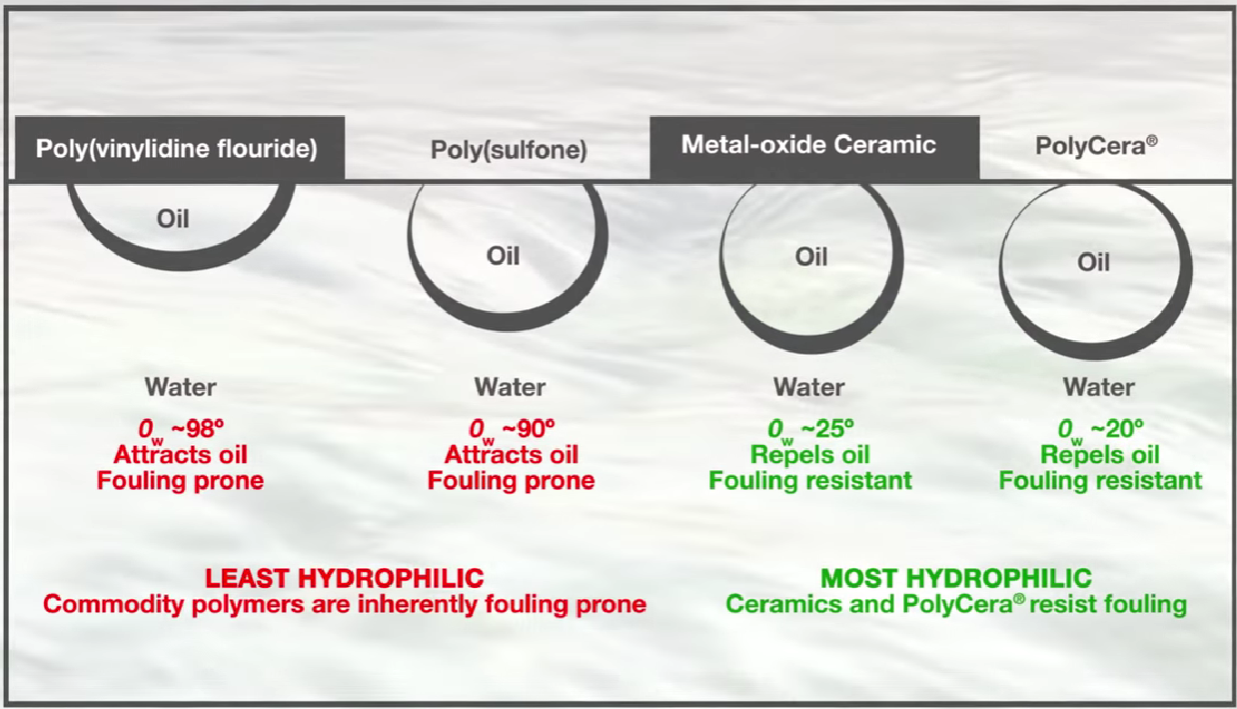

PolyCera membranes offer a unique combination of extreme hydrophilicity, permeability and robustness. Improved hydrophilicity means improved fouling resistance and ease of cleaning, ultimately more water and less cost. PolyCera membranes were developed to tackle most challenging industrial application, delivering stable performance under extreme pH, temperature, fouling and chemical conditions.

BENEFITS

- Oleophobic, lower Operating cost, low energy demand, less process down-time, maintain high flux, low irreversible fouling, handles challenging waters, reduces chemical demand and minimized waste

APPLICATIONS

- Produced water, mining, refineries, automotive, oily wastewater, anaerobic digestate, power generation, chemicals and textiles.

POLYCERA MEMBRANE SERIES

- Hydro-UF250 & Hydro-UF100: High temperature, corrosion and fouling resistance

- Titan-UF70: High temperature and corrosion resistance. High oil removal rate.

- Titan-NF500: For COD reduction and material separation.

PolyCera® is a new polymeric material platform derived from Nobel Prize winning polymer chemistry developed into membrane materials at the University of California, Los Angeles (UCLA) and the California NanoSystems Institute (CNSI).

PolyCera polymer materials are 100% organic, but they exhibit unique electronic behaviour that shifts from metal-like conducting to metal oxide-like semi-conducting to plastic-like insulating properties. These materials are neither conventional polymers nor are they traditional metals or metal-oxide ceramics. PolyCera goes beyond traditional polymeric and ceramic materials.

For Further Information: https://polyceramembranes.com/

AWARDS